ZAF Energy Systems Inc. (ZAF)*, a developer of next-generation battery technology, and Wirtz Manufacturing (Wirtz), a global leader in equipment design and technology for the lead-acid battery market, have announced that they has issued Wirtz purchase orders to complete phase one of their scaled-up manufacturing line.

The equipment will expand ZAF’s manufacturing capacity from hundreds of batteries per month to thousands of batteries per month in Joplin facility.

This added capacity will allow them to rapidly seed the market and meet the growing customer demand for its rechargeable nickel-zinc (NiZn) batteries globally.

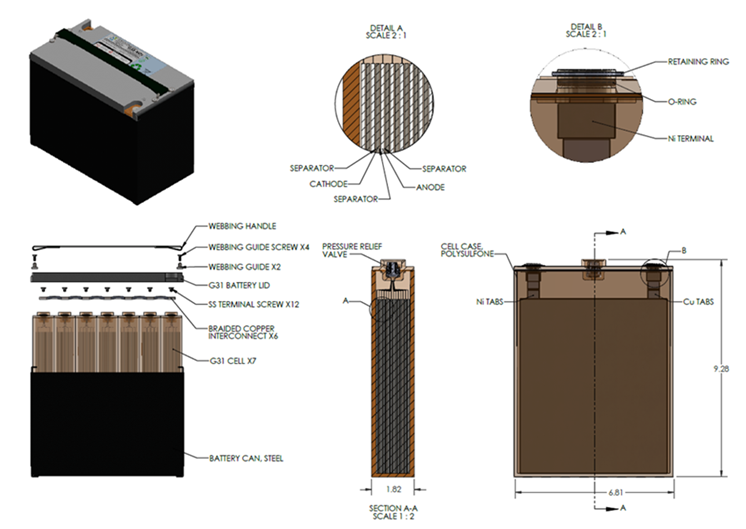

Wirtz has a long history of driving new technology innovations in the battery industry. Its demonstration showed how to coat electrodes using lead-acid manufacturing equipment with very little modification, thus offering further validation of the commercial readiness of the ZAF’s NiZn battery technology.

The advanced line includes computer-controlled touch change capabilities. This technology is not included in many existing battery assembly lines.

These batteries are helping to meet customer demands for powerful, cost-effective, and environmentally friendly battery solutions. NiZn batteries have potential uses in a wide range of applications, including: automotive, heavy trucking, remote telecom, renewable energy, and marine.

NiZn batteries are poised to disrupt the $60 billion conventional lead-acid battery market with their ability to provide twice the storage capacity and three times the power of legacy lead-acid batteries in a smaller, lighter package.

Reference- ZAF website PR, Wirtz Manufacturing (Wirtz) website, Clean Technica