The issue of waste in the fashion industry has gotten a lot of attention recently, and for good reason. Millions of tonnes of clothing are created, used, and discarded each year. A large portion of such waste occurs at the consumer level, when consumers discard clothing that still has some wearable life in it.

According to the United Nations Environment Program, “the number of times a garment is worn has declined by 36% in 15 years,” illustrating the growing influence of throwaway culture on fashion.

The apparel sector is a major source of plastic microfibres entering our oceans. With that in mind, let us take a look at start up unspun’s latest 3D weaving machine.

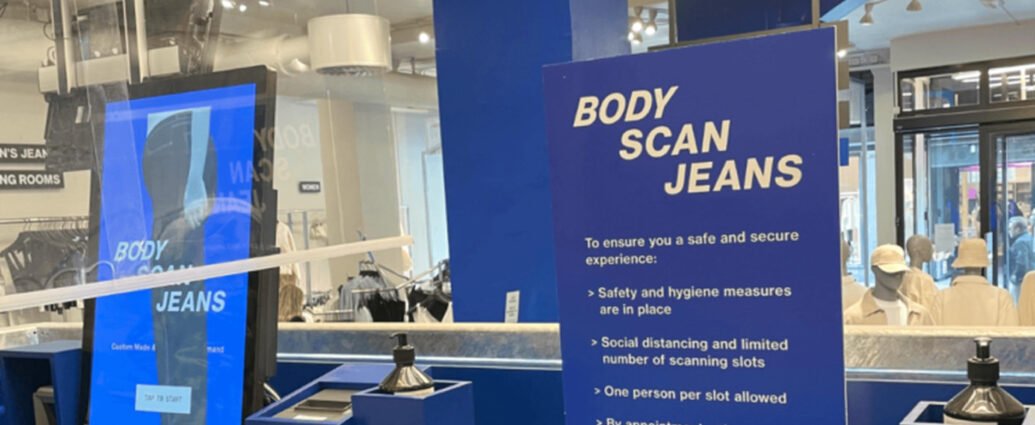

Unspun was founded in 2015 with the goal of reducing waste at the consumer level. The startup uses 3D scanning to perfectly fit individual buyers’ jeans and creates them on demand. With the bespoke fit and the premium but relatively low price tag of $200 or more, buyers should be compelled to retain their jeans for a long time.

Aside from encouraging consumers to stop throwing away their garments, the on-demand manufacturing approach virtually eliminates the massive amount of waste that occurs when merchants purchase too many products at the start of a season, only to discard the unsold ones at the end.

Unspun is now turning its attention to the fabric waste angle, with the launch of its new trademarked Vega 3D weaving machines. To ice the green cake, unspun is also investigating ways to retrieve and re-use yarn from finished garments.

If the 3D weaving machines are yarn-agnostic, there could be other recycling pathways in the mix. We’re thinking that could include synthetic yarns made from recycled plastics, recycled carbon, and other waste sources.

Reference- Unspun PR & Online Newsroom, Clean Technica, Futurism, Interesting Engineering, Triple Pundit website