Smart textiles have a lot of cool uses for wearable tech, like helping with therapy, sensing things, and staying connected. But for these smart fabrics to work well, they gotta be tough, flexible, and able to conduct electricity. However, creating fibers with these three qualities is difficult and needs complex conditions and systems.

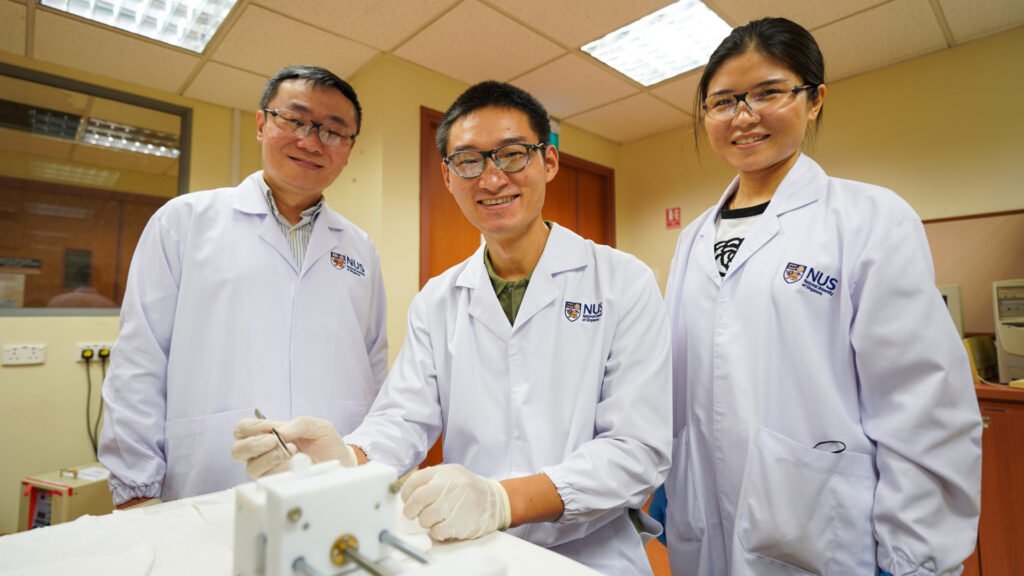

Taking inspiration from how spiders spin silk to create webs, a group of researchers from the Materials Science and Engineering Department at the National University of Singapore’s College of Design and Engineering, along with their global partners, have come up with a cool way to make soft fibers. These fibers have all the three important qualities mentioned above and can be effortlessly recycled to make more fibers.

The process can be done at room temp and pressure, and it uses less solvent and energy too, which makes it a great choice for making soft fibers for smart stuff.

The NUS team thought it’d be cool to copy Spider’s natural spinning process and make soft fibres that are strong, stretchy, and can conduct electricity. They identified two unique steps in spider silk formation that they could mimic.

Making spider silk involves turning a super concentrated protein solution, called silk dope, into a fiber strand. The researchers found out that the protein concentration and interactions in the silk dope increase as they go from making the dope to spinning it.

They also discovered that the proteins in the dope change their arrangement when triggered by external factors, which helps to separate the liquid part from the solid part and create the spider silk fibers. This process is called liquid-solid phase separation.

The team decided to redo the two steps and came up with a fresh spinning method called the phase separation-enabled ambient (PSEA) spinning approach. When compared to other ways of making fiber, this new spider-inspired method uses a lot less energy and fewer chemicals.

Thus, researchers were able to make soft fibers that are strong, stretchable, and electrically conductive by using the biomimetic spinning process and a special gel solution.

Reference- National University of Singapore (NUS), Interesting Engineering, Clean Technica, Journal Nature Electronics, Popular Mechanics