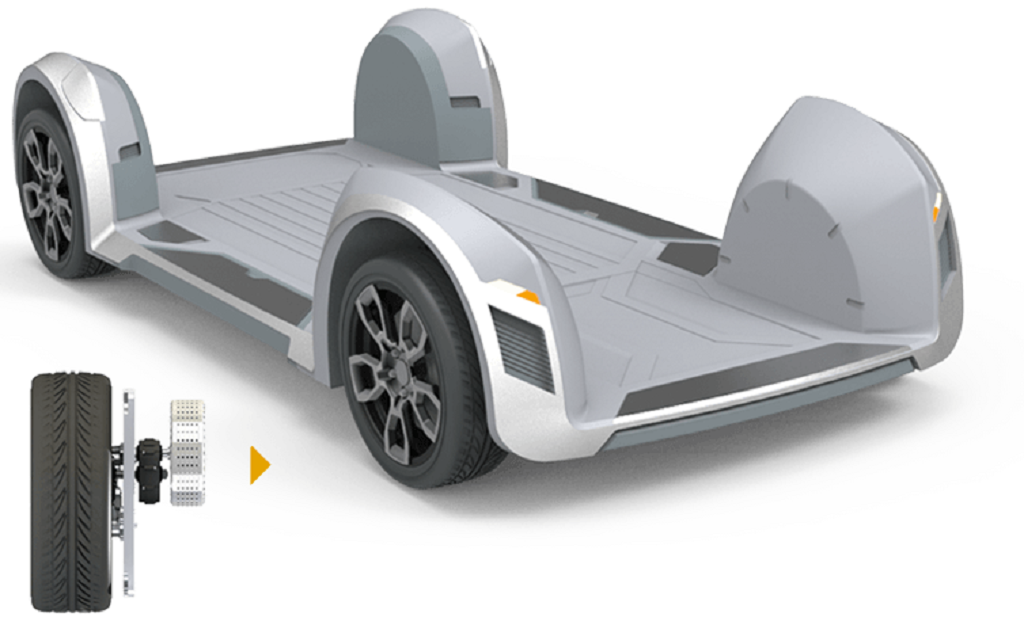

A Tel Aviv based startup by the name of REE Automotive is working on a standardized undercarriage, which can be used to build any type of vehicle on top of it. A very recent example of this was showcased by electric truck maker ‘Rivian.’

REE feels that this is the best way to make EVs mainstream and takes the approach of standardized flatbeds farther than ever before due to the volume and drive controls that REE flatbed can accommodate. Their flatbed can hold the most batteries per footprint than anybody else in the industry.

Standardized flatbeds are essentially the easier way out for EV makers to produce a range of vehicles on a single platform.

Their idea integrates the battery, motors and driving controls into the floor in a way that results in independent steering of wheels. Such an arrangement is able to reduce the cost of production of an EV drastically.

So no wonder traditional auto makers were attracted to the idea. Tokyo-based KYB Corp., one of the world’s biggest makers of shock absorbers, recently formed a partnership with them to develop suspension system for electric vehicles based on their platform. The partnership will result in KYB’s first ever electric vehicle.

Apart from KYB, REE is also working with Mitsubishi Corp., FiatChrysler and Hino, a Toyota-affiliated truckmaker.

There are other advantages that REE’s platform promises.

While lowering production cost of a vehicle, the platform will also result in lighter and compact EVs as they not only 33% lighter, but are almost 70% smaller in footprint” in comparison with Tesla Model 3 having the same interior volume.

Reference- Times of India, REE PR & Online Newsroom, InsideEVs