Green hydrogen is basically hydrogen that is made using electrolyzer systems, where they use renewable energy and catalysts to separate water into hydrogen and oxygen.

Iridium, a super rare metal, is a key ingredient in the electrolyzer systems used to produce green hydrogen. Like, it’s really Rare. The metal is found in extremely low concentrations in the earth’s crust — at approximately 0.000003 parts per million and South Africa was the country which accounted for almost 90% of virgin iridium on the market as of last year.

The market for green hydrogen is booming, and experts predict that soon there won’t be enough iridium-powered systems to keep up with the demand.

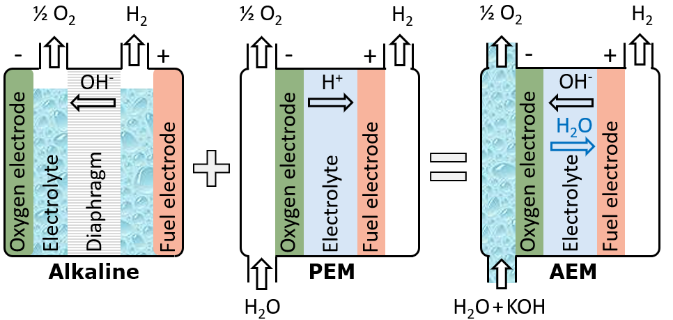

Iridium is a huge stumbling block in the quest for cheap and eco-friendly green hydrogen. Basically, iridium oxide catalysts are the ones responsible for producing oxygen in a polymer electrolyte membrane (PEM) electrolyzer system.

Even though it’s expensive and not so easily available, the companies who are into PEM still choose iridium because it’s super efficient, stable, and long-lasting.

One way to solve this is by finding other catalysts that work just as well as iridium but are cheaper and easier to come by. For example, scientists are looking into using a catalyst made of ruthenium oxide with nickel. Another company called H2U Technologies is also optimistic about their PEM system that doesn’t use iridium.

Other electrolyzer systems are also starting to be used. Specifically, anion exchange membrane (AEM) systems have been stepping up their game. Other companies are also developing and commercializing AEM electrolyzers, including Alchemr, EvolOH and HydroLite, but all of these are still a work in progress.

As a new player in the game, green hydrogen only makes up around 1% of the hydrogen supply worldwide. The rest, a whopping 99%, still relies on natural gas, and to a smaller extent, coal. So, there’s definitely a long way to go before green hydrogen catches up.

It’s gonna take a while for green hydrogen to pick up speed and become as cheap as fossil-sourced hydrogen. Right now, green hydrogen costs about $5.00 per kilogram, but it needs to go down to $1.00 to really compete.

Reference- Ammonia Energy article, Wikipedia, Rice University PR, H2U Technologies PR, Clean Technica