Aluminum is increasingly being used as a lightweight and sturdy building material, but the process of mining and refining it results in high energy use and greenhouse gas emissions. The production of 1 ton of aluminum emits an average of 17 tons of carbon dioxide and requires 16.6 megawatt hours of electricity.

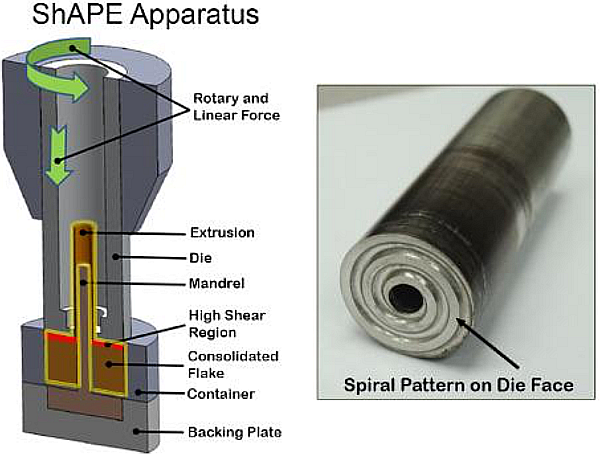

A new technology called Shear Assisted Processing and Extrusion Process (ShAPE™, developed at the US Department of Energy’s Pacific Northwest National Laboratory (PNNL) has closed the loop on scrap aluminum in the circular economy. This means that used aluminum items like twisted mesh, bicycle frames, and car parts can be repurposed into building structures without using much energy.

The ShAPE manufacturing process stands out because it uses heat generated by high shear forces to break down impurities in scrap aluminum and evenly distribute them throughout the aluminum microstructure.

ShAPE aluminum extrusion removes small iron clumps that can cause microfractures in recycled aluminum products made through traditional methods. This process saves a significant amount of energy by eliminating the requirement to mix impurities in recycled aluminum with newly mined aluminum before manufacturing.

The technology has been proven to convert 100% post-consumer aluminum scrap into usable extrusions that meet or surpass the strength and flexibility requirements set by ASTM for building-grade alloys 6061 and 6063.

The ShAPE manufacturing process conserves energy and eliminates greenhouse gas emissions on several fronts. First, It avoids the need to add primary aluminum. Then, it eliminates the need for homogenization of the billet material, a 6- to 24-hour heat treatment near 500 °C prior to extrusion, plus the elimination of the need to add newly mined aluminum greatly reduces the manufacturing cost,

Reference- PNNL Newsroom, Clean Technica, Interesting Engineering