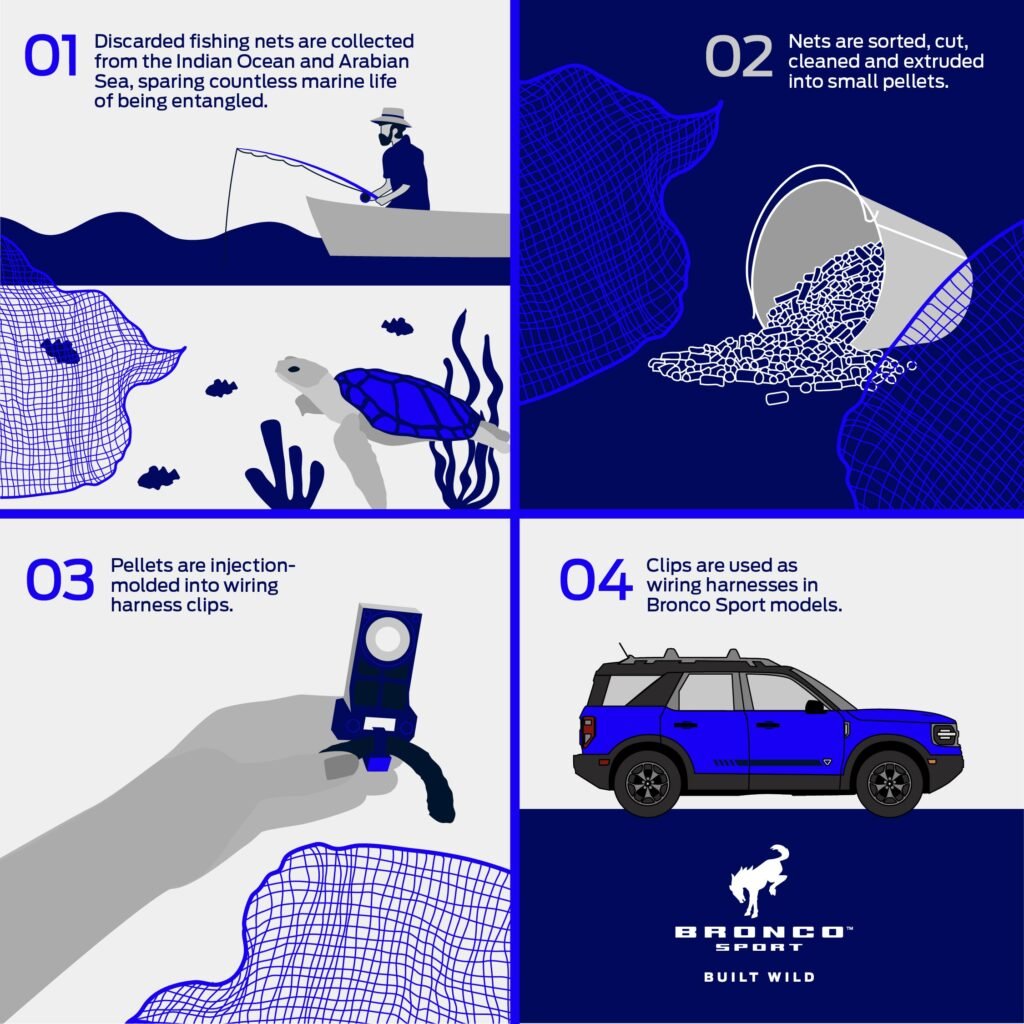

Ford has just launched a new automobile part manufactured from recovered fishing nets, or “ghost gear,” which the firm is touting as the auto industry’s first usage of recycled ocean plastic. They want to provide a variety of components produced from recycled ocean plastic.

It’s natural to believe Ford’s new recyclable plastic automobile component is a marketing trick. However, the business claims that the recycled plastic clip costs 10% less than the normal kind and requires less energy to manufacture.

The company showcased the innovative recycled plastic clip on the Bronco Sport, where it will be used to secure the cables connecting to the vehicle’s side air bags. Although the new part is small, it has thrown a greenish hue throughout the Bronco.

Along with cost savings, Ford believes that the new recycled plastic clip outperforms virgin plastic in terms of performance. That is also a significant improvement from only a few years ago.

Historically, recycled plastic had limited applications due to its lower performance. In general, the majority of plastics have been downcycled for use in carpet fibre, textiles, and other products. Recent advancements, however, have enabled recycled plastic to penetrate new sectors.

The performance threshold might be raised much higher if and when next-generation recycling technology becomes commercially available, which would break down plastics into chemical building blocks for reassembly.

Ford also believes that plastic automobile parts contribute significantly to vehicle weight reduction, resulting in increased battery range for electric vehicles.

Reference- Ford Online Newsroom, Inside EVs, Ford Authority,