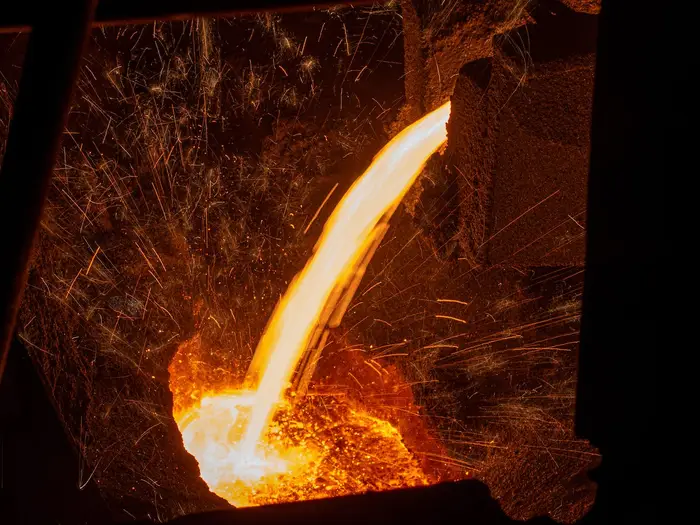

Norsk Hydro created the world’s first aluminum using green hydrogen to power the smelting process. The Norwegian company, one of the world’s top aluminum producers, smelted 225 tonnes of recovered aluminum at its facility in Navarra, Spain, with three batches powered by a hydrogen-fossil-gas blend and six by pure hydrogen.

It now intends to investigate how changes in the way hydrogen burns compared to methane impact both the whole aluminum smelting process and metal purity, with results expected this autumn. The business also intends to use the aluminum test batches to manufacture further items.

Hydro Havrand, Hydro’s green hydrogen subsidiary, conducted and led the test. Reportedly, the tests used around 33,000 normal cubic metres (2,966kg) of hydrogen produced via electrolysis, which was supplied by Nippon Gases.

To be “green,” hydrogen must be produced using renewable energy such as sun, wind, or hydropower.

Because renewable energy is required for so many purposes in the global green energy transition, particularly for electricity, redirecting too much green energy into hydrogen generation may be detrimental.

The International Renewable Energy Agency (IRENA) has issued a new study warning against the “indiscriminate use of hydrogen,” advising policymakers to carefully assess their objectives and consider that substantial use of hydrogen “may not be in line with the requirements of a decarbonised world.”

Reference- Hydrogen Insight, Bloomberg, Business Insider, Reuters, IRENA Report