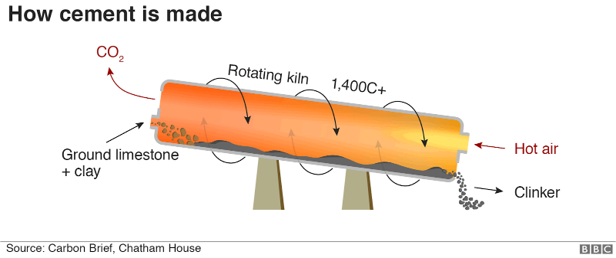

Producing Portland cement is actually responsible for around 8% of all carbon emissions worldwide each year. And there are a couple of reasons behind this. Firstly, in order to create the essential ingredients for cement, limestone has to be heated up to around 2700º F in huge kilns. This process requires a significant amount of energy, usually obtained by burning methane gas.

Secondly, this chemical reaction occurring inside the kilns actually releases even more carbon dioxide.

But, check this out! There’s this new company called Sublime Systems that can totally make cement without all those huge carbon emissions. And, they just announced that their low carbon, super versatile alternative for concrete has officially been given the ASTM C1157 designation.

Meeting that standard allows Sublime cement to be used in making concrete that meets or even surpasses the relevant US and international building codes. This opens up a way for it to replace regular Portland on a large scale, resulting in a significant reduction in the carbon emissions of the global construction industry.

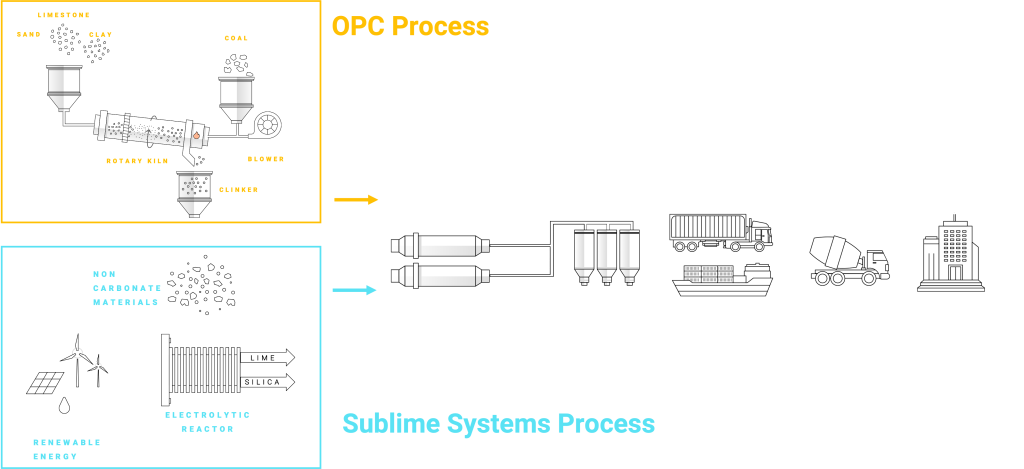

Sublime Systems has developed a threefold approach to reduce carbon dioxide emissions in production.

- Firstly, they use renewable electricity instead of fossil fuels.

- Secondly, their process operates at room temperature, eliminating the need for excessive heating.

- Lastly, they utilize non-carbonate raw materials instead of limestone, which releases carbon dioxide when heated.

Sublime Cement is made with a “true-zero” (instead of net-zero) method, so there’s no need for offsets or extra carbon capture and storage infrastructure to cut down on emissions.

Reference- Sublime Cement Online Newsroom & PR, Interesting Engineering, Clean Technica, BBC, Popular Science, ASTM International website