Working globally through their respective and established project teams in the US and China, BAK and Cadenza Innovation carried out project feasibility assessments, safety testing, institutional testing, and other third-party testing on Cadenza Innovation’s supercell architecture.

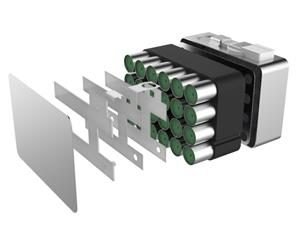

Once satisfied, both companies gave a final go ahead to the signing of an agreement under which Shenzhen BAK Power Battery and Cadenza Innovation will co-manufacture lithium-ion (Li-ion) cells using supercell architecture which provides reliable safety, lower cost, and high energy density by combining small ‘jelly roll’ cells in a ceramic material to create larger cells.

Once satisfied, both companies gave a final go ahead to the signing of an agreement under which Shenzhen BAK Power Battery and Cadenza Innovation will co-manufacture lithium-ion (Li-ion) cells using supercell architecture which provides reliable safety, lower cost, and high energy density by combining small ‘jelly roll’ cells in a ceramic material to create larger cells.

Cadenza Innovation’s patented supercell architecture is designed for the 2 fastest-growing markets: electric vehicles and grid storage. The Cadenza “supercell” differs from conventional lithium-ion batteries by eliminating cobalt from the mix for the cathode.

The battery can be manufactured using traditional ‘jelly roll’ production machinery, which helps drive down costs. The cells are then packaged in a unique matrix that insulates them from each other to prevent cascading failures in the event one cell has a malfunction.

The number of cells in each block can be adjusted to meet the particular needs of the customer. For more energy, one needs do no more than add more blocks.

Fire retardants are an important part of Cadenza’s proprietary battery block. That’s why it can be shipped anywhere in the world by conventional means, as it doesn’t burn in regular temperatures and has fire retardants mixed in.

Cadenza Innovation was recently named a World Economic Forum 2018 Technology Pioneer.

Reference- Cadenza Innovation PR, Cleantechnica