The simple fact is that plain old water is the only large scale, long duration energy storage medium available as of today. The challenge is that water batteries — aka pumped hydropower — require expensive new infrastructure, which limits their application.

That could be about to change, , and it looks like the US Department of Energy is determined to be the change maker.

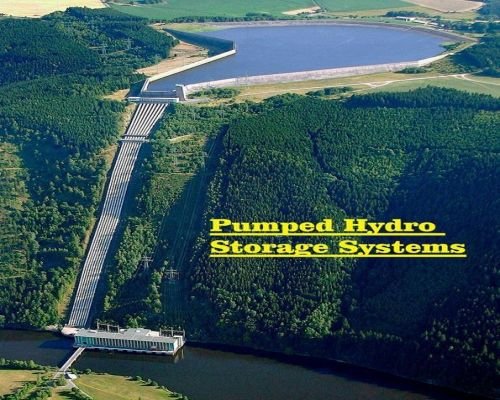

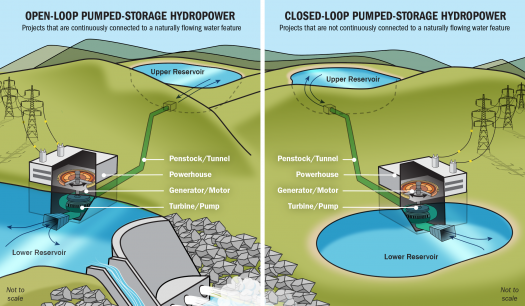

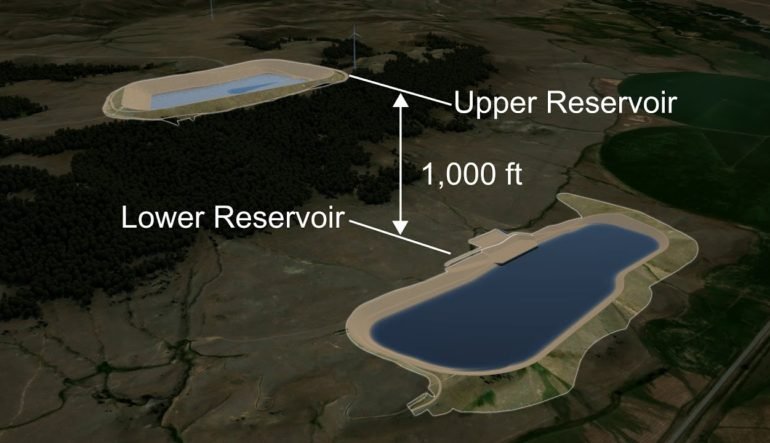

For those of you new to the topic, pumped hydro can take advantage of renewable energy to pump water from a lower reservoir to an upper reservoir.

When the local grid needs more electricity, gravity does the rest. Water from the upper reservoir scoots downhill to run turbines, and ends up in the lower reservoir.

Allowing for variables like evaporation, runoff, and planned releases, a closed loop pumped hydro system is also a nifty way to recycle water resources.

The main point, though, is that bulk, long duration energy storage can provide bottom line support for new clean power projects.

However, building new pumped hydro facilities means building more infrastructure, and that’s where the bottleneck is.

Site selection and cost are both key roadblocks. Building the underground infrastructure required for conventional pumped hydro is a costly, tedious, high risk venture, and there is no one-size-fits all approach.

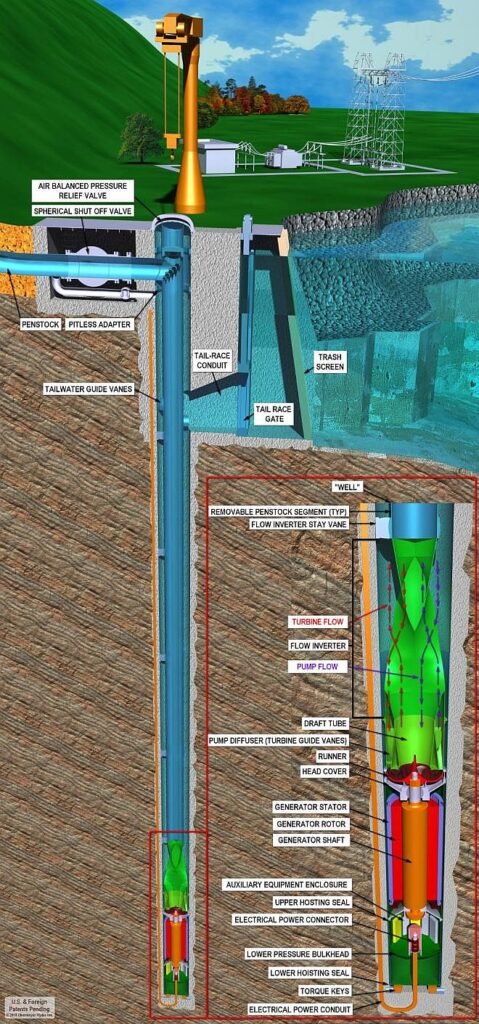

One of the projects to emerge from the Energy Department’s focus on energy storage is a new pumped hydro turbine design from the firm Obermeyer Hydro Inc. They were awarded $1.18 million to develop an advanced closed-loop pumped-storage hydropower (PSH).

Key to this new design is that it does not require an underground powerhouse, which is one of the more costly, risky, and environmentally impactful aspects of PSH [pumped-storage hydropower] construction.

An economic analysis of Obermeyer’s new design indicates that ditching the underground powerhouse would result in a 45% savings in construction costs, as the main feature in a 33% reduction in overall costs for the project.

This pump-turbine design has the potential to be used in a wide range of closed-loop and open-loop pumped storage projects, using combinations of aboveground and underground reservoirs, seawater, and potable water storage.

Non-storage applications include high-efficiency pumps for water supply and conveyance and premium-efficiency well pumps.

Reference- NREL Research Report, US Department of Energy, Obermeyer Hydro Inc website & PR, Clean Technica