According to Fleetzero, a New Orleans-based startup, container ships account for 2.2 percent of worldwide carbon dioxide emissions — almost a billion tonnes per year — as well as 15% of nitrogen oxides and 13% of sulphur oxides.

With the goal of making container ships more environmentally friendly, Fleetzero has designed a 2-megawatt-hour lithium iron phosphate battery (LFP Battery) pack that can fit within a 20′ by 5′ shipping container. Load enough containers onboard (or tow them behind on a barge) to finish a sea journey, then change them out for fully charged replacements when they are exhausted while the ship is in port to load or unload goods.

Fleetzero claims that their approach is less expensive than long-haul transportation between port cities, even when first and last mile fees are included in.

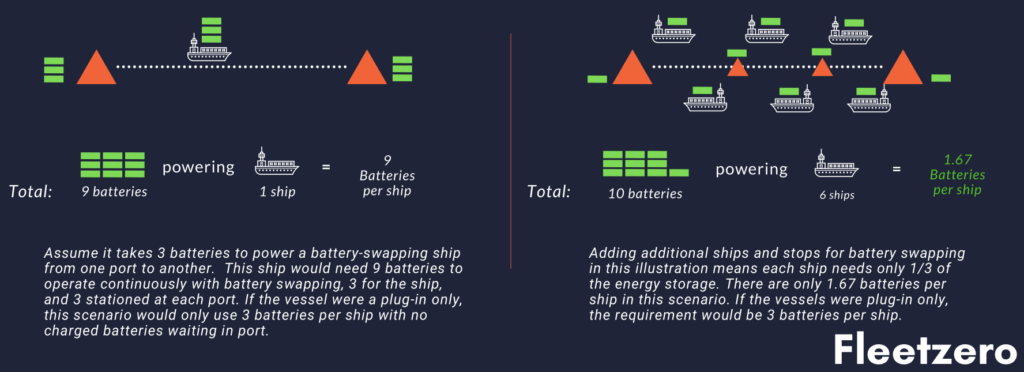

The strange economics of this are that the more ships and stops you have, the cheaper your cost is. The idea is to make the batteries swappable – something that would not be possible with a plug-in vessel.

Because the batteries are placed in containers, current shipping cranes can simply load and unload them. They can be recharged at ports or trucked inland to charging points with more strong electrical infrastructure. The American Bureau of Shipping has approved Fleetzero’s container battery technology for vessel propulsion.

It will be difficult to persuade maritime businesses to accept the concept of battery-powered ships. However, the company is counting on the same economic drivers that make electric trucks and buses appealing to fleet operators: reduced overall cost of operation.

Reference- TechCrunch, Electrive, Inside EVs, The Maritime Executive, Clean Technica