More than 90% of wind energy plants in the United States started producing electricity during the previous decade. Between 2025 and 2040, an estimated 10,000 to 20,000 blades will reach the end of their useful life. Wind power plant owners will increasingly have to make judgments on what to do with these blades.

The freely accessible Circular Economy Wind Agent-Based modelling tool developed by NREL researchers attempts to solve this question by presenting alternatives and solutions. According to the researchers, in the absence of policy changes or advancements in recycling technology, up to 78% of decommissioned blades are expected to end up in landfills.

High transportation costs and subjective standards, which deter individuals from recycling blades if they witness others not doing so, are two reasons impeding recycling. Recycling blades would become the standard if enough early users encouraged them.

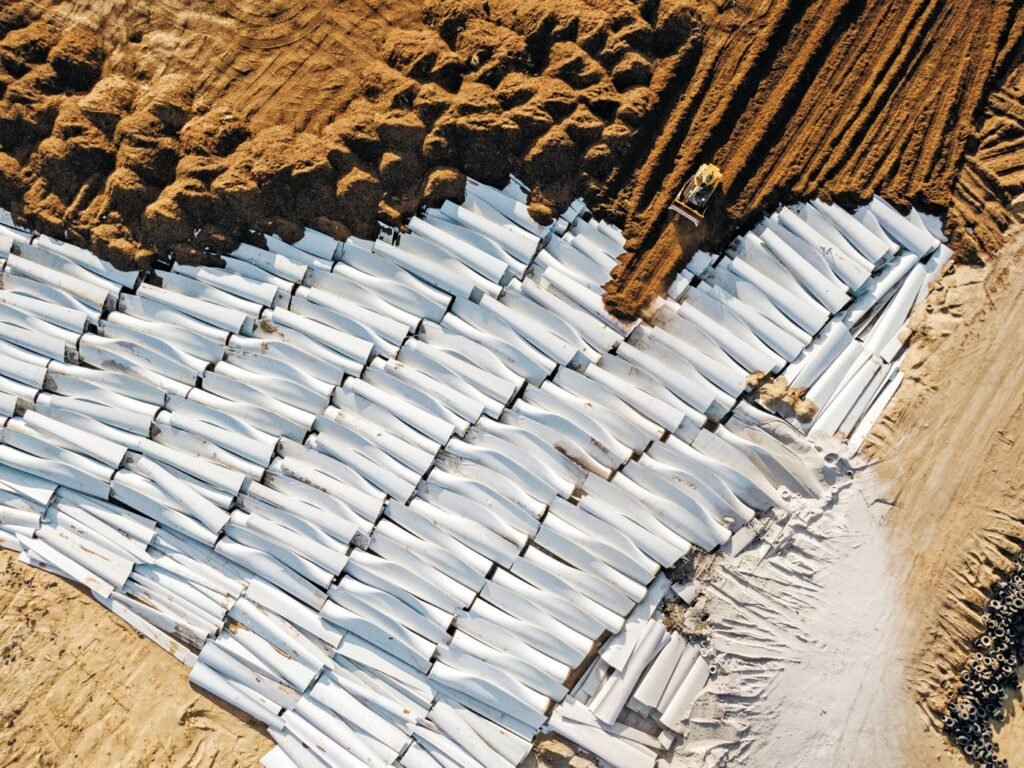

Reduced transportation costs could have a significant impact on how old blades are disposed of. Steel, plastic, and composite materials are commonly used to make the blades. While many of the materials presently routinely used for blades are readily broken down, with the correct machinery, they can also be shredded.

Shredding the blades reduces their size and makes them easier to transport to a recycling plant. Even a third reduction in the cost of shredding blades before shipping might bring the cumulative landfill rate below 50%. Another scenario that entails encouraging early recycling adoption such that it becomes the norm might reduce the amount to less than 10%.

Meanwhile, other NREL researchers are also developing novel materials for blades in order to increase their recyclability. These developments might lead to a circular economy for wind turbine blades.

Reference- NREL website, Science Direct, Clean Technica, Interesting Engineering, iScience article